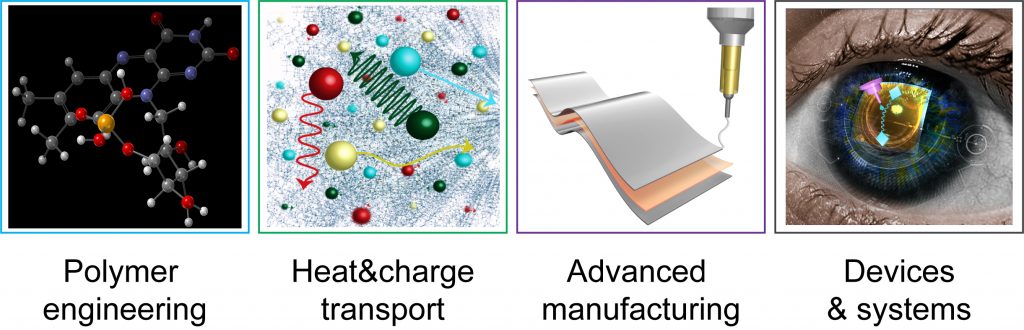

Our research is comprised of four interrelated areas of investigation: polymer engineering, heat and charge transport, advanced manufacturing, devices and systems (Figure 1).

Figure 1. Research topics.

Figure 1. Research topics.

First, we explore the fundamental relationships between polymer structures and properties at the atomic level; then, we engineer polymers to improve their thermal and electrical properties; next, we integrate these new materials into thermal and electrical devices and systems through advanced manufacturing. Along with improving the manufacturing process, we also enhance the functionality of these thermal and electrical properties.

Our Lab Research Facilities

Laser facilities for determining temperature-dependent thermal diffusivity (-125 oC – 600 oC).

Laser facilities for determining temperature-dependent temperature-dependent thermal conductivity (-190 oC – 600 oC).

Facilities for determining temperature-dependent specific heat (-90 oC – 600 oC).

Facilities for determining Seebeck Coefficient and electrical conductivity (25 oC – 1100 oC).

Thermal transport in polymers

While functioning well as electrical insulators, polymers are poor thermal conductors (~0.1 W/m-K). Turning polymer heat insulator into heat conductor will provide new opportunities for various applications ranging from electronics cooling, thermal biosensor and thermal energy storage and conversion, to big data, artificial intelligence, and soft robotics. To transform polymer thermal insulator to thermal conductor, we need a better understanding of the relationships between thermal transport properties and structures.

Figure 2. Polymers’ chemical, structural and morphological complexity. Polymer structure at (A) atomic and molecular level and (B) nanoscale and mesoscale level.

By a combination of ultrafast lasers, high-resolution electron microscopes and synchrotron X-ray scattering techniques, we are explaining the relationship between thermal transport and polymer structures from the macroscopic to the atomic levels so we can develop this new platform of multiscale structured polymers with controlled thermal properties. (Figure 2 and 3).

Figure 3. (A) Multi-scale investigation of transport property in polymers.(B) Polymer backbone structure effect (bond stretching and segmental rotation etc.) on thermal transport.(C) Structural characterization using synchrotron X-Ray scattering . Thermal conductivity measurement using (D) time-domain thermoreflectance technology and (E) steady-state method. (F) Thermal interface resistance measurement.

Energy storage devices: supercapacitors & microsupercapacitors

Electrical energy storage at high charge and discharge rates is an important technology in today’s society because it not only enables plug-in electronics to work well, but also provides backup for wind and solar energy. In electrochemical systems, it is believed that very high power rates can be achieved with supercapacitors. But the current energy density of supercapacitors is low. We advance the fundamental understanding of charge and ion transport mechanisms (Figure 4), design structural polymers with controlled composition, microstructures, architectures and conformations across multiple length scales, and create polymer-based electrodes with high energy and power densities. In addition, these electrodes and electrolytes have high thermal conductivity, so we address potential overheating problems during the charge and discharge processes.

Figure 4. Explore fundamental relationships between polymer structure and heat/charge transport.

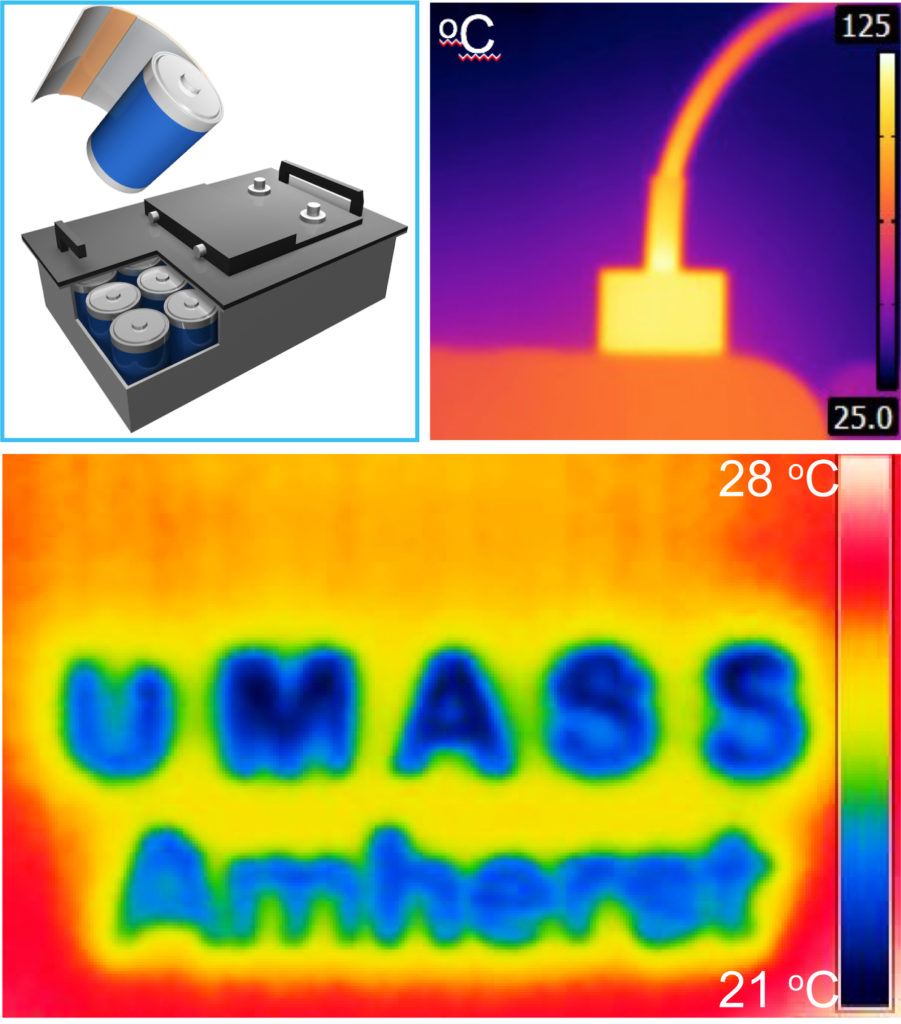

Advanced manufacturing

By leveraging UMass Amherst’s manufacturing platforms and our research group’s advanced functional materials, we create devices with locally controlled microstructures, not accessible by conventional processing methods, using 3D printing, inkjet printing, and inkjet molding. We translate these materials into integrated devices and systems through advanced manufacturing, and enhance functionality during the manufacturing process. Combining advanced materials and advanced manufacturing, we can design and develop high-performance devices and systems, such as supercapacitors for better energy storage and conversion, and thermal sensors for better biomedical temperature imaging (Figure 5).

Figure 5. Integrated devices fabricated by advanced manufacturing. For example, supercapacitor and thermal sensor.

UMassAmherst Manufacturing Facilities:

https://www.umass.edu/ials/roll-to-roll-fabrication

UMassAmherst Core Facilities: https://www.umass.edu/ials/core-facilities

NSF Center for Hierarchical Manufacturing at the University of Massachusetts Amherst: http://chm.pse.umass.edu

Figure 6. NSF center for hierarchical manufacturing at the University of Massachusetts Amherst. (A) Roll-to-roll nanoimprint lithography. (B) Roll-to-roll coating. (C) Microgravure coating. (D) Thermal nanoimprinting. (E) Mask and bond alignment. (F) Nanoindentation. (G) Besi Datacon 2200 Evo Plus R2R pick and place/bonding tool for hybrid integration. (H) Desktop inkjet printer.

- International and Domestic Research Collaborations/Support

Professor Xinliang Feng at Technische Universität Dresden (link), Max Planck Institute of Microstructure Physics (link), distinguished professor at Shanghai Jiao Tong University (link).

Professor Renhao Dong at Technische Universität Dresden (link), professor at Shandong University, professor at The University of Hong Kong.

Professor Sheng Shen at Carnegie Mellon University (link).

Professor Mengqiang Zhao at New Jersey Institute of Technology (link).

Professor Mingda Li at Massachusetts Institute of Technology (link).

Professor Shengxi Huang at Rice University (link).

Dr. Zhang Jiang at Argonne National Laboratory (link).

Dr. Ruipeng Li at Brookhaven National Laboratory (link).

Sponsors

- Faculty Startup Fund Support from the University of Massachusetts Amherst.

- CUMIRP Research Cluster F (Fire-Safe Polymers & Polymer Composites).

- Federal Aviation Administration

- National Aeronautics and Space Administration

- Massachusetts Space Grant Consortium

- National Science Foundation